By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Maximize Your Machine’s Performance with Superior Mechanical Rack and Pinion Gears

Mechanical Rack and Pinion Gears play a crucial role in converting rotational motion into precise linear movement across numerous industrial and automation applications. These components are fundamental in CNC machines, robotics, and material handling systems, where accuracy and reliability are non-negotiable. A well-designed Mechanical Rack and Pinion Gears system minimizes backlash, improves stiffness, and ensures efficient power transmission—attributes that are critical in high-performance environments. For example, advanced systems have been shown to reduce linear backlash by up to 50% and enhance overall power density, a testament to the precision and quality of modern Mechanical Rack and Pinion Gears Source: STOBER Drives Inc..

When selecting Mechanical Rack and Pinion Gears, it is essential to consider the material quality, gear tooth precision, and the overall design integration with your equipment. These gears are typically engineered from hardened steel or other high-strength alloys, ensuring durability under high loads and extended use. Their design is refined through computer-aided engineering (CAE) to achieve optimal alignment between the pinion and the rack. This precise configuration not only minimizes friction but also ensures smooth, consistent motion. As a result, upgrading to top-tier Mechanical Rack and Pinion Gears can significantly boost the performance and longevity of your machinery.

The science behind Mechanical Rack and Pinion Gears is fascinating. In a typical setup, the rack—a straight bar with evenly spaced gear teeth—meshes with a rotating pinion. The geometry of this engagement determines how effectively the rotational motion is converted into linear movement. Any deviation in alignment or tooth profile can lead to inefficiencies and premature wear. Therefore, investing in high-quality Mechanical Rack and Pinion Gears is not just a matter of performance but also of maintenance cost reduction over time. Modern manufacturers now offer a range of options that include both straight and helical-toothed pinions, catering to specific application needs and load conditions.

Advanced applications demand that Mechanical Rack and Pinion Gears not only transfer motion effectively but also adapt to different operational speeds. For instance, high-force systems require gears that can handle substantial torque without compromising on precision. Meanwhile, high-speed applications benefit from designs that reduce inertia and minimize vibrations. These specialized features ensure that every Mechanical Rack and Pinion Gears system can be tailored to meet the exacting standards of modern automation. The integration of lubrication systems and robust mounting brackets in these products further ensures that they maintain peak performance under continuous operation.

The versatility of Mechanical Rack and Pinion Gears is a major reason for their widespread adoption in both industrial and hobbyist projects. Whether you’re working on a full-scale production line or a custom-built robotics project, the right gear system can dramatically enhance control and efficiency. Manufacturers often provide extensive customization options, including various pitch diameters and module sizes, which allow for seamless integration with standard metric racks. This adaptability is essential when designing systems that demand precise movement control over varying distances and loads.

Top 10 Best Mechanical Rack and Pinion Gears to Buy

- Model: 0.5 Mod; Size: 8mm x 8mm / 0.31″ x 0.31″; Total Length: 500mm / 20″

- Made of 45# carbon steel, it has better hardness, higher strength and resistance to deformation than ordinary A3 steel.

- More durable and long lasting than nylon gear racks.

- [Vehicle Fitment]: Compatible with Chevrolet Silverado 1500 1999-2006; Compatible with GMC Sierra 1500 1999-2006 — For…

- [Important Note]: It comes with Inner Outer Tie Rods and Dust Boots; It fits the model with Hydraulic Power Steering. It…

- [Package Details]: 1 x Rack and Pinion Steering Assembly + 2 x Outer Tie Rods

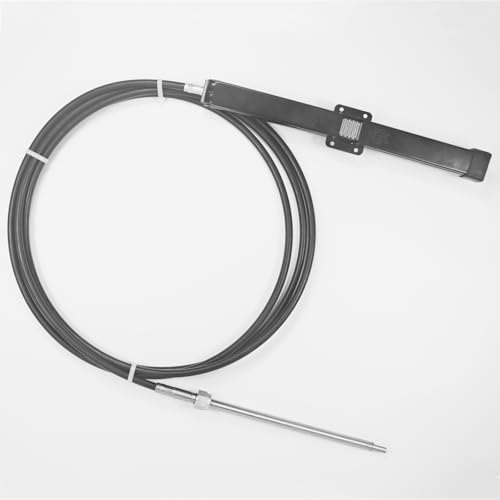

- 【20ft Rack Pinion Steering Cable】-The 20 foot Rack Steering Cable is long enough to reserve enough space for your operat…

- 【Universal Compatibility】-Part Number SSC13420. The rack steering cable has passed the ship environment test. Widely app…

- 【High Tensile Strength】- Marine steering cables are durable and can withstand the dynamic forces of steering, sea winds,…

- RACK PINION TRANSFER LINES FITMENT: Compatible with 2007-2008 GMC Yukon XL 1500, 2007-2008 GMC Yukon, 2007-2008 GMC Sier…

- PACKAGE INCLUDES: 15254059 15254058 Rack Pinion Transfer Lines

- UPGRADE MATERIAL: MITZONE rack and pinion transmission line is made of high-quality metal with silver corrosion-resistan…

- Pinion Gear: Model: 0.5 Mod; Teeth: 20T; Bore Size (Shaft Dia.): 4mm / 0.16″; Outer Dia. (Teeth Part): 11mm / 0.43″; Eff…

- Brass Parts: The brass pinion gear has strong wear resistance, high strength, high hardness and chemical corrosion resis…

- Easy to Use: Be sure your RC motor shaft have the same diameter. Comes with set screws for each pinion gear, easy to ins…

- 【❗Fitment Details❗:】Only for Models with: Engine Code LLV | VIN 9 | 4WD |

- ✅【OE Standards:】Our Product Is Designed And Manufactured With Modern Tooling, Ensuring Optimal Quality And Reliability

- ✅【Quality Manufacturing:】Replacement Parts are Specifically Designed as an Upgrade from the Original Materials Provided …

- [Vehicle Fitment]: Compatible with Chevrolet Impala 2004-2005 (with Special Ride, Handling Suspension (FE4)), Impala 200…

- [Important Note]: It comes with Inner Tie Rods and Dust Boots; It fits the model with Hydraulic Power Steering; In-Line …

- [Part Number]: 22-1012, 221012, 19207777, 88955466, 88964322

- 【❗Fitment Details❗:】Rack and Pinion Seal Kit | Notes: 4WD |

- ✅【OE Standards:】Our Product Is Designed And Manufactured With Modern Tooling, Ensuring Optimal Quality And Reliability

- ✅【Quality Manufacturing:】Replacement Parts are Specifically Designed as an Upgrade from the Original Materials Provided …

- 【❗Fitment Details❗:】

- ✅【OE Standards:】Our Product Is Designed And Manufactured With Modern Tooling, Ensuring Optimal Quality And Reliability

- ✅【Quality Manufacturing:】Replacement Parts are Specifically Designed to the Same Specifications and Use Better, More Dur…

For those in the automation and robotics sectors, choosing the best Mechanical Rack and Pinion Gears is key to achieving reliable and accurate performance. Many experts recommend that before making a purchase, you review detailed technical specifications, customer testimonials, and independent test reports. The best products in this category feature low friction designs, high load-bearing capacities, and minimal backlash—all of which contribute to a smoother operational experience. Additionally, the inclusion of comprehensive installation kits and technical support can ease the integration process, ensuring that your new Mechanical Rack and Pinion Gears work optimally from day one.

Engineers and technicians appreciate that high-quality Mechanical Rack and Pinion Gears not only improve the performance of existing systems but also pave the way for innovative applications in new technologies. In sectors like CNC machining, precision in linear motion translates directly into higher quality outputs and reduced waste. Similarly, in robotics, precise gear systems enable more accurate and repeatable movements, which are essential for complex tasks. As the market evolves, continuous improvements in design and materials are setting new standards, making today’s Mechanical Rack and Pinion Gears more efficient and durable than ever before.

Furthermore, these gear systems are increasingly being integrated with smart monitoring technologies. Some advanced systems now offer built-in sensors that track gear performance and wear, providing real-time data to help with predictive maintenance. This technology ensures that any potential issues are addressed before they lead to significant downtime, thereby saving costs and maintaining productivity. By investing in top-of-the-line Mechanical Rack and Pinion Gears, you are not only enhancing the current capabilities of your machinery but also future-proofing your operations against emerging challenges.

For both new adopters and seasoned professionals, understanding the mechanics behind Mechanical Rack and Pinion Gears is essential. Knowledge of the precise interplay between the rack and pinion can help in troubleshooting issues and optimizing performance. Experts suggest that regular maintenance, including proper lubrication and alignment checks, is crucial to sustain the longevity of these systems. This level of attention to detail ensures that your equipment remains in peak condition, providing consistent results and minimizing the risk of costly repairs.

In summary, the selection of premium Mechanical Rack and Pinion Gears can significantly impact the efficiency, precision, and durability of your machinery. With rigorous testing, innovative design, and advanced materials, the best Mechanical Rack and Pinion Gears provide superior performance in even the most demanding industrial applications. Whether you’re upgrading an existing system or designing a new one, these gear systems are an investment in both quality and long-term productivity. Make sure to research, compare technical specifications, and choose products that meet your specific operational needs to maximize your machinery’s potential.

“As an Amazon Associate we earn from qualifying purchases.”